Japanese kitchen knives have a long and rich history dating back centuries, and they have undergone a number of significant changes and innovations over the years.

From the early use of bronze to the introduction of tamahagane and hagane steel, the evolution of Japanese kitchen knives has been shaped by a combination of cultural influences and technological advancements.

Today, Japanese kitchen knives are highly prized for their sharpness, durability, and precision, and they are used by professional chefs and home cooks around the world.

In this article, we will explore the fascinating history and evolution of Japanese kitchen knives, highlighting the key events and innovations that have shaped the development of these iconic tools.

Table of contents

- The early history of Japanese kitchen knives, introduction of bronze as a material for knife making

- The development of steel kitchen knives during the Kamakura period and the rise of tamahagane as a favored material

- The evolution of Japanese kitchen knives during the Edo period

- The role of traditional Japanese sword-making techniques in the creation of modern Japanese kitchen knives

- The use of different materials in modern Japanese kitchen knife production, including carbon steel, stainless steel, and high-carbon stainless steel

- The various types of Japanese kitchen knives and their specific uses

- The cultural significance of Japanese kitchen knives in Japanese cuisine and the importance of craftsmanship in their production

- The popularity of Japanese kitchen knives outside of Japan and their growing popularity among professional chefs and home cooks around the world

- The future of Japanese kitchen knife-making, including the potential for the use of new materials and the role of modern production techniques.

The early history of Japanese kitchen knives, the introduction of bronze as a material for knife making

The early history of Japanese kitchen knives can be traced back over a thousand years, to a time when the nobility of ancient Japan used bronze knives for ceremonial purposes.

These early knives were likely similar to the bronze knives used by other cultures around the world at the time, and they were primarily used in rituals and ceremonies rather than for everyday tasks.

As time passed, however, bronze kitchen knives began to be used more widely in everyday life. Bronze was a popular material for knife-making due to its durability and corrosion resistance; it was also relatively easy to work with.

As a result, bronze kitchen knives became a common sight in Japanese kitchens, with many families owning at least a few basic knives for everyday use. Despite the widespread use of bronze kitchen knives, they were still largely considered a luxury item.

Only the wealthy and powerful could afford to own a large collection of bronze knives, and they were often used to display one's social status and wealth. As metalworking techniques improved, new materials such as steel began to be used for the production of kitchen knives.

This marked the beginning of a new era in the evolution of Japanese kitchen knives, and it set the stage for the development of the sharp, precise, and durable knives that are so highly prized today.

The development of steel kitchen knives during the Kamakura period and the rise of tamahagane as a favored material

The Kamakura period, which lasted from 1185 to 1333, marked a significant turning point in the history of Japanese kitchen knives.

During this time, Japanese swordsmiths began to experiment with the production of steel kitchen knives, using a type of steel known as "tamahagane." Tamahagane was created by heating iron sand to extremely high temperatures and then hammering it into the desired shape.

The process was labor-intensive and required a high level of skill, but it resulted in a type of steel that was highly prized for its durability and sharpness. Tamahagane was used to make many of the swords used by the samurai during this period, and it was also used for the production of high-quality kitchen knives.

The use of tamahagane for kitchen knife production marked a major step forward in the evolution of Japanese kitchen knives.

Prior to this, kitchen knives were mostly made of bronze, which was a less durable and less sharp material. The use of tamahagane allowed for the production of knives that were both stronger and sharper, making them much more effective tools in the kitchen.

As the popularity of tamahagane kitchen knives grew, the production of bronze knives began to decline.

While bronze knives were still used in some cases, they were increasingly being replaced by tamahagane knives, which were considered to be of higher quality and more suitable for everyday use.

Today, tamahagane is still highly prized in Japan and is used in the production of a variety of high-quality steel products, including kitchen knives.

While the production techniques have evolved over time, the traditional method of creating tamahagane steel is still used by some craftsmen, and it remains a symbol of the skill and expertise that goes into the making of Japanese kitchen knives.

The evolution of Japanese kitchen knives during the Edo period

The Edo period, which lasted from 1603 to 1868, was a time of great change and innovation in Japan, and this was reflected in the evolution of Japanese kitchen knives as well.

During this time, a new type of steel called "hagane" was introduced, and it quickly became the material of choice for the production of Japanese kitchen knives.

Hagane was even harder and more durable than tamahagane, the type of steel that had previously been used for kitchen knife production.

This allowed for the production of thinner, lighter, and more precise knives, which were highly prized by both professional chefs and home cooks.

In addition to the introduction of hagane steel, the Edo period also saw the development of the distinctive curved blade and tsuka handle that are now associated with many Japanese kitchen knives.

These features were inspired by the traditional Japanese sword, or "katana," which was known for its curved blade and tsuka handle.

The adoption of these features allowed for a more comfortable and efficient grip, and they also contributed to the aesthetic appeal of the knives.

The use of hagane steel and the development of the curved blade and tsuka handle marked a major shift in the design of Japanese kitchen knives.

These innovations allowed for the creation of knives that were stronger, sharper, and more comfortable to use, and they set the stage for the modern Japanese kitchen knives that are so highly prized today.

The role of traditional Japanese sword-making techniques in the creation of modern Japanese kitchen knives

Japanese sword-making techniques have played a significant role in the creation of modern Japanese kitchen knives.

These techniques, which have been passed down through the generations, are based on a long tradition of craftsmanship and attention to detail.

One of the key techniques used in the production of traditional Japanese swords is known as "forging."

This process involves heating the steel to a high temperature and then hammering it into shape using a variety of specialized tools.

The precise temperature and hammering technique used can have a significant impact on the strength, durability, and sharpness of the final product.

Many of the same techniques used in the production of traditional Japanese swords are also used in the creation of modern Japanese kitchen knives. For example, the process of forging is often used to shape and harden the blade of a kitchen knife, resulting in a stronger and sharper tool.

Other techniques, such as "tempering," which involves heating and cooling the steel to specific temperatures in order to improve its properties, are also used in the production of modern Japanese kitchen knives.

In addition to the use of traditional techniques, many Japanese kitchen knife makers also place a strong emphasis on craftsmanship and attention to detail.

This includes the use of high-quality materials and the application of traditional techniques such as "hand-polishing," which involves carefully smoothing and shaping the blade by hand using specialized tools.

The combination of traditional techniques and a focus on craftsmanship has helped to make Japanese kitchen knives some of the finest and most highly prized in the world.

Whether you're a professional chef or a home cook, a Japanese kitchen knife can be a valuable addition to your kitchen, thanks in part to the centuries of tradition and expertise that go into its creation.

The use of different materials in modern Japanese kitchen knife production, including carbon steel, stainless steel, and high-carbon stainless steel

Japanese kitchen knives are made using a variety of materials, each with its own unique properties and characteristics.

The most common materials used in the production of Japanese kitchen knives include carbon steel, stainless steel, and high-carbon stainless steel.

Carbon steel is a type of steel that contains a high percentage of carbon. It is known for its sharpness and durability, and it is often used in the production of Japanese kitchen knives.

Carbon steel knives are highly prized by professional chefs and home cooks alike for their ability to hold a sharp edge, but they do require more maintenance than other types of knives.

Carbon steel knives are prone to rusting if they are not properly cared for, and they may require more frequent sharpening due to their tendency to dull more quickly. Stainless steel is another popular material for Japanese kitchen knife production.

It is known for its corrosion resistance and durability, and it is often used in the production of knives that will be used in wet or humid environments.

Stainless steel knives are generally easier to care for than carbon steel knives, as they are less prone to rusting and staining.

However, they are generally not as sharp as carbon steel knives and may require more frequent sharpening.

High-carbon stainless steel is a hybrid material that combines the sharpness and durability of carbon steel with the corrosion resistance of stainless steel.

It is often used in the production of Japanese kitchen knives that are intended for everyday use, as it offers a balance of sharpness and ease of maintenance.

High-carbon stainless steel knives may require less frequent sharpening than carbon steel knives, but they may still dull more quickly than stainless steel knives.

In addition to these materials, some Japanese kitchen knife makers also use other types of steel, such as "VG-10," which is a type of high-carbon stainless steel that is known for its sharpness and durability.

Regardless of the material used, the goal of Japanese kitchen knife makers is to create knives that are sharp, durable, and comfortable to use, and that can withstand the demands of the kitchen.

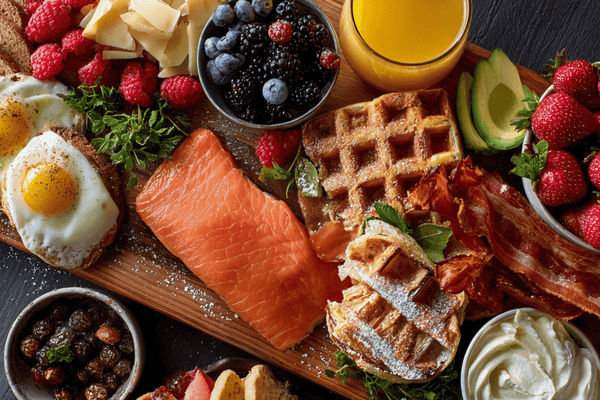

The various types of Japanese kitchen knives and their specific uses, such as the deba knife for filleting fish and the santoku knife for slicing and dicing

Japanese kitchen knives come in a wide variety of shapes and sizes, each designed for a specific purpose. Some of the most common types of Japanese kitchen knives and their uses include

Deba knife: This is a heavy, thick-bladed knife that is primarily used for filleting and preparing fish. The deba knife has a pointed tip and a sharp edge, which allows it to easily cut through the bones and flesh of fish. It is also sometimes used for preparing meats and poultry.

Santoku knife: The santoku knife is a versatile all-purpose knife that is similar to a Western chef's knife. It has a shorter, wider blade that is well-suited for slicing, dicing, and mincing a wide variety of ingredients. The santoku knife is a popular choice for home cooks due to its versatility and ease of use.

Nakiri knife: The nakiri knife is a type of vegetable knife with a long, thin, rectangular blade. It is designed specifically for chopping and slicing vegetables, and it is often used in traditional Japanese cuisine. The nakiri knife has a straight edge and a flat, squared-off tip, which makes it well-suited for slicing vegetables into thin, even slices.

Usuba knife: The usuba knife is another type of vegetable knife that is similar to the nakiri knife. It has a long, thin blade with a sharp, pointed tip, and it is primarily used for precision cutting and slicing of vegetables. The usuba knife is often used in traditional Japanese cuisine, and it is prized for its ability to make clean, precise cuts.

Gyuto knife: The gyuto knife is a type of chef's knife that is similar to a Western chef's knife. It has a long, thin blade with a pointed tip, and it is used for a variety of tasks, including slicing, dicing, and mincing. The gyuto knife is a popular choice for professional chefs due to its versatility and ability to handle a wide variety of tasks.

These are just a few of the many types of Japanese kitchen knives that are available, and there are many others to choose from as well.

Whether you're a professional chef or a home cook, there is a Japanese kitchen knife that can meet your needs and help you achieve the best results in the kitchen.

The cultural significance of Japanese kitchen knives in Japanese cuisine and the importance of craftsmanship in their production

Japanese kitchen knives are an integral part of Japanese cuisine and culture, and they are highly prized for their sharpness, durability, and precision.

In Japan, the craft of kitchen knife-making is steeped in tradition and is considered a highly skilled and respected profession.

Japanese kitchen knives are used in a variety of dishes, including sushi, sashimi, and other raw fish dishes, as well as cooked dishes such as tempura, teriyaki, and stir-fries.

The sharpness and precision of Japanese kitchen knives are particularly important in the preparation of raw fish dishes, as they allow the chef to slice the fish into thin, even slices with minimal effort.

In addition to their practical uses, Japanese kitchen knives also hold a place of cultural significance in Japanese cuisine.

In Japan, the art of cooking is highly respected, and the tools used in the kitchen are considered an extension of the chef's skills and expertise.

As a result, Japanese kitchen knives are often carefully chosen and well-maintained, and they are seen as a symbol of the chef's dedication to their craft. The production of Japanese kitchen knives is also a highly respected and traditional art form.

Many Japanese kitchen knife makers are craftsmen who have spent years learning and perfecting their skills, and they take great pride in their work.

The process of making a Japanese kitchen knife is a time-honored tradition that involves a variety of specialized techniques, including forging, tempering, and hand-polishing.

In summary, Japanese kitchen knives are an important part of Japanese cuisine and culture, and they are highly valued for their sharpness, durability, and precision.

The art of kitchen knife-making is steeped in tradition and is considered a highly skilled and respected profession, and the craftsmanship that goes into the production of Japanese kitchen knives is an integral part of their appeal.

The popularity of Japanese kitchen knives outside of Japan and their growing popularity among professional chefs and home cooks around the world

Japanese kitchen knives have gained widespread popularity outside of Japan in recent years, and they are now used by professional chefs and home cooks around the world.

There are several reasons for their growing popularity, including their sharpness, durability, and precision. One of the main reasons for the popularity of Japanese kitchen knives is their sharpness.

Japanese knives are known for their ability to hold a very sharp edge, which makes them ideal for tasks such as slicing and dicing.

This is due in part to the high-quality materials used in their production, as well as the traditional techniques employed by Japanese knife makers.

In addition to their sharpness, Japanese kitchen knives are also highly prized for their durability.

Many Japanese kitchen knives are made using materials such as carbon steel and high-carbon stainless steel, which are known for their strength and resistance to wear and tear.

This makes them well-suited for use in the kitchen, where they can withstand the demands of daily use. Another reason for the popularity of Japanese kitchen knives is their precision.

Japanese knives are often carefully crafted using traditional techniques, and this attention to detail allows for the creation of knives that are highly precise and well-balanced.

This is particularly important for tasks such as slicing raw fish, where a sharp, precise blade is essential for achieving the desired results.

The popularity of Japanese kitchen knives has also been fueled by their increasing availability outside of Japan.

In recent years, more and more Japanese knife makers have begun exporting their products, making it easier for people around the world to purchase and use Japanese kitchen knives.

Overall, Japanese kitchen knives have gained widespread popularity among professional chefs and home cooks around the world due to their sharpness,

The future of Japanese kitchen knife-making, including the potential for the use of new materials and the role of modern production techniques.

The future of Japanese kitchen knife-making looks bright, with many exciting developments on the horizon.

One of the most significant trends in Japanese kitchen knife-making is the use of new materials, which have the potential to improve the performance and durability of Japanese kitchen knives.

One potential new material that has garnered a lot of attention in recent years is ceramic.

Ceramic kitchen knives are known for their extreme sharpness and lightweight, and they have the potential to revolutionize Japanese kitchen knife-making.

While ceramic knives have been around for some time, recent advances in production techniques have made them more durable and suitable for use in the kitchen.

Another trend in Japanese kitchen knife-making is the use of modern production techniques, such as laser cutting and 3D printing.

These techniques allow for the creation of knives with precise, complex shapes and patterns, and they have the potential to revolutionize the way that Japanese kitchen knives are made.

In addition to the use of new materials and production techniques, there is also a growing trend towards sustainability and environmental responsibility in Japanese kitchen knife-making.

Many knife makers are exploring the use of recycled materials and eco-friendly production techniques to minimize their impact on the environment.

Overall, the future of Japanese kitchen knife-making looks bright, with many exciting developments on the horizon.

Whether it's the use of new materials, modern production techniques, or a focus on sustainability, there is no doubt that Japanese kitchen knives will continue to evolve and improve in the coming years.

So, we can expect to see many innovative and high-quality Japanese kitchen knives in the future.